Looking at energy issues and green solutions, and now increasingly reporting on the phenomenon, which includes zero point energy, zero gravity, and many more mysteries of Non Human Intelligence, NHI.

Wednesday, 16 March 2022

Nickel hydrogen batteries long lasting and dependable

Hubble Space telescope used them for 19 years before replacement!

more from wikipedia, here is the highlights;

The nickel-hydrogen battery combines the positive nickel electrode of a nickel-cadmium battery and the negative electrode, including the catalyst and gas diffusion elements, of a fuel cell. During discharge, hydrogen contained in the pressure vessel is oxidized into water while the nickel oxyhydroxide electrode is reduced to nickel hydroxide. Water is consumed at the nickel electrode and produced at the hydrogen electrode, so the concentration of the potassium hydroxide electrolyte does not change. As the battery discharges, the hydrogen pressure drops, providing a reliable state of charge indicator. In one communication satellite battery, the pressure at full charge was over 500 pounds/square inch (3.4 MPa), dropping to only about 15 PSI (0.1 MPa) at full discharge.

If the cell is over-charged, the oxygen produced at the nickel electrode reacts with the hydrogen present in the cell and forms water; as a consequence the cells can withstand overcharging as long as the heat generated can be dissipated.[dubious – discuss]

The cells have the disadvantage of relatively high self-discharge rate, i.e. chemical reduction of Ni(III) into Ni(II) in the cathode:

{\displaystyle {\ce {NiOOH + 1/2H2 <=> Ni(OH)2.}}}{\displaystyle {\ce {NiOOH + 1/2H2 <=> Ni(OH)2.}}}

which is proportional to the pressure of hydrogen in the cell; in some designs, 50% of the capacity can be lost after only a few days' storage. Self-discharge is less at lower temperature.[1]

Compared with other rechargeable batteries, a nickel-hydrogen battery provides good specific energy of 55-60 watt-hours/kg, and very long cycle life (40,000 cycles at 40% DOD) and operating life (> 15 years) in satellite applications. The cells can tolerate overcharging and accidental polarity reversal, and the hydrogen pressure in the cell provides a good indication of the state of charge. However, the gaseous nature of hydrogen means that the volume efficiency is relatively low (60-100 Wh/L for an IPV (individual pressure vessel) cell), and the high pressure required makes for high-cost pressure vessels.[1]

The positive electrode is made up of a dry sintered[20] porous nickel plaque, which contains nickel hydroxide. The negative hydrogen electrode utilises a teflon-bonded platinum black catalyst at a loading of 7 mg/cm2 and the separator is knit zirconia cloth (ZYK-15 Zircar).[21][22]

The Hubble replacement batteries are produced with a wet slurry process where a binder agent and powdered metallic materials are molded and heated to boil off the liquid.[23]

Designs

Individual pressure vessel (IPV) design consists of a single unit of NiH2 cells in a pressure vessel.[24]

Common pressure vessel (CPV) design consist of two NiH2 cell stacks in series in a common pressure vessel. The CPV provides a slightly higher specific energy than the IPV.

Single pressure vessel (SPV) design combines up to 22 cells in series in a single pressure vessel.

Bipolar design is based on thick electrodes, positive-to-negative back-to-back stacked in a SPV.[25]

Dependent pressure vessel (DPV) cell design offers higher specific energy and reduced cost.[26]

Common/dependent pressure vessel (C/DPV) is a hybrid of the common pressure vessel (CPV) and the dependent pressure vessel (DPV) with a high volumetric efficiency.[27]

alternatives to lithium batteries are lower cost, longer duration

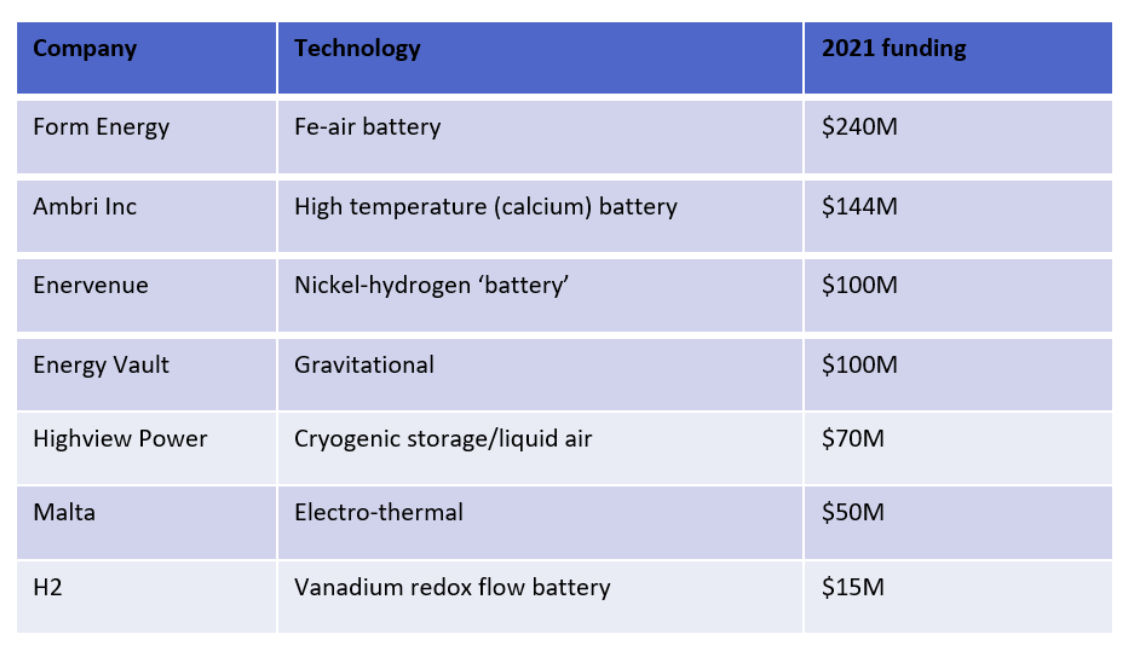

Various battery chemistries based on zinc, iron, and other low-cost materials are also being developed and commercialized. Interest in these alternatives can be highlighted by some of the funding raised in 2021 from companies developing these long-duration technologies, including the $200 million for Form Energy’s iron-air, $144 million for Ambri Inc’s high-temperature battery, and $100 million for Enervenue’s nickel-hydrogen hybrid battery,” the report reads.

“Companies developing non-electrochemical storage technologies such as Highview Power and Energy Vault have also raised considerable funding in 2021.”

Non-lithium battery chemistries to grow in importance for stationary energy storage sector - report

(Source: IDTechEx).

IDTechEx’s review predicts that several factors playing against the lithium-ion industry could open opportunities for battery chemistries, and energy storage technologies, that utilize lower cost, more widely available materials and that can also offer additional safety and environmental benefits.

The analyst’s data show that the second half of the 2020s could see lithium, cobalt, and nickel supply disruptions and bottlenecks, while the sector will also have to deal with the ongoing questioning of the safety and environmental credentials of materials throughout the Li-ion supply chain.

“Li-ion will continue to dominate the energy storage space in the short term. For battery electric vehicles, this will continue to be the case even in the long-term as there are few realistic alternatives beyond related chemistries based on silicon and lithium-metal anodes or solid-electrolytes,” the report reads.

But for stationary storage, IDTechEx predicts alternatives to Li-ion are set to play an increasingly important role due to their potential for improving cost and safety, easing material supply burdens, and the often less demanding requirements on energy density in the stationary sector.

Subscribe to:

Comments (Atom)